Compressor application

Air bearings for product handling

With air bearings or pneumatic casters, heavy loads can be easily moved using heavy loads virtually suspended on a cushion of essentially frictionless air.

Press paper

Compressed air is passed through rollers for a variety of printing applications.

printing

Control of printing pumps and equipment via compressed air. The air will not explode, safe and reliable.

Ink roller adjustment

Precise control of the thickness of the ink roller via compressed air, which determines the thickness of the paper, is key to ensuring the effectiveness of the process.

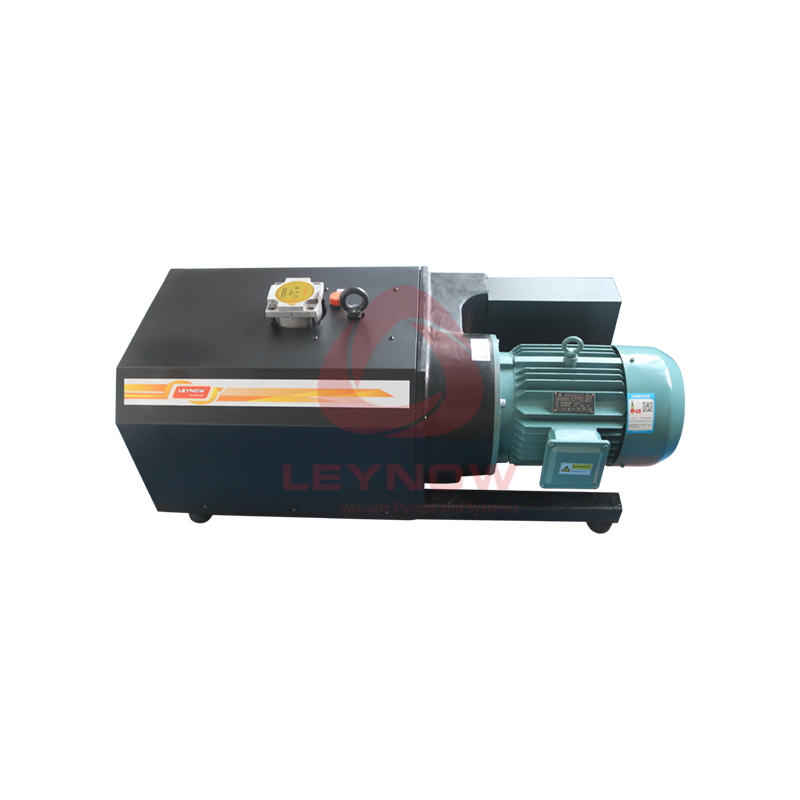

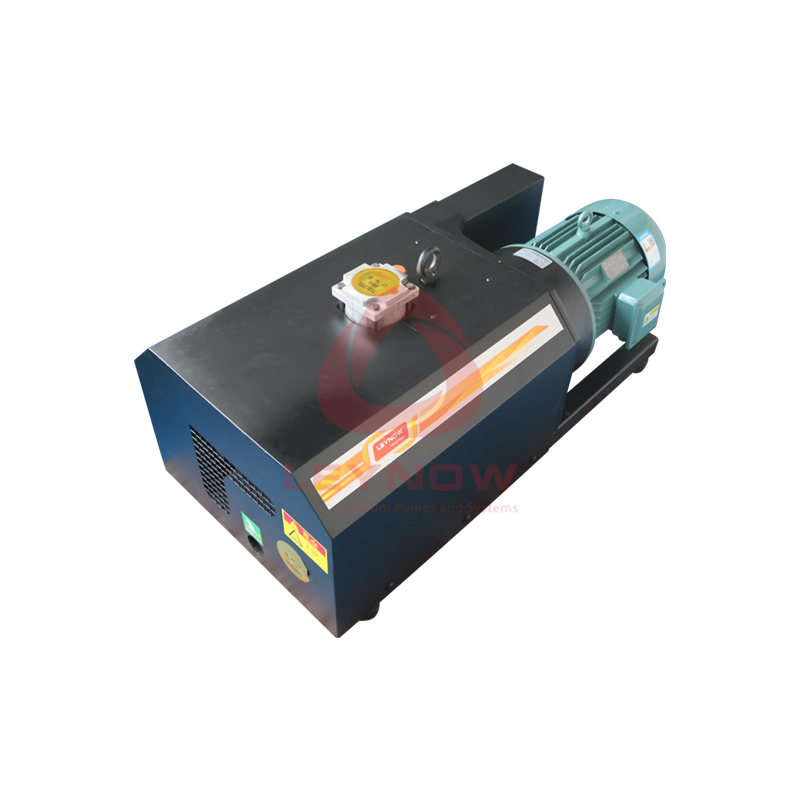

vacuum generation

Using compressed air and venturi systems, the vacuum used in a variety of production processes, such as product processing, can be effectively generated.

Blower and vacuum applications

Clean liquid handling

In pulp and paper mill ancillary service equipment/processes, centrifugal pumps are used for liquid handling, cleaning and extraction.

Pre-press, in-press and post-press applications

Vacuum is necessary for a variety of pre-printing applications, including preparing images and films for scanning or exposing and drying printing plates. Many applications also require overpressure to guide printing plates or films in automated systems. In conventional sheet-fed offset printing presses, vacuum and overpressure are always required during sheet handling – in the feed unit to separate sheets, to transport individual sheets to different color collecting units or to guide sheets through the printing press.

All of these applications require different amounts of air at different pressures. Pumps and compressors are widely used in post-printing applications. For example, side-flow fans are used in folding and cutting machines; pressure-vacuum pumps and separate vacuum pumps and compressors are used in collating and bookbinding machines; and centrifugal fans are used to remove waste paper.

pulp drying

Vacuum is applied throughout the forming section of the paper machine to remove moisture from the papermaking raw material. The water suction box and lying roller in the forming section use different vacuum levels to remove most of the moisture.

Pulp processing

Various pulps are processed through process centrifugal pumps (a variety of impellers can be selected according to the different viscosities and densities of the liquids being processed).

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN