Compressor application

CNG vehicle refueling

With over 2,000 CNG compression units supplied worldwide, Gardner Denver is a global leader in the design, manufacture and installation of ready-to-run CNG refuelling stations, offering three decades of unrivalled engineering pedigree.

Our global team meets the needs of a diverse range of customers through a series of modular, ready-to-run packages based around the Gazpack range of air and water cooled reciprocating compression units. The Gazpack series is designed to cover the full range of station types from pilot projects and small forklift fleets, through to high capacity public stations and large bus/truck refuelling depots. Designed for flexibility and ease of installation, the Gazpack series is available in a wide range of packaging options. In addition to Gardner Denver's unrivalled knowledge base in compression solutions and reciprocating unit manufacture, the organisation can also support you with its extensive expertise in project management.

Our team of experienced project managers and engineers can advise on all aspects of this process, taking into account the station and fleet type as well as its proposed purpose, full volume, site limitations and budget. Should you require a fast fill system for public forecourts or a time fill system for vehicles being left over night, our engineers can design a filling system to meet your needs, complete with a full range of ancillaries.

Compressed air applications

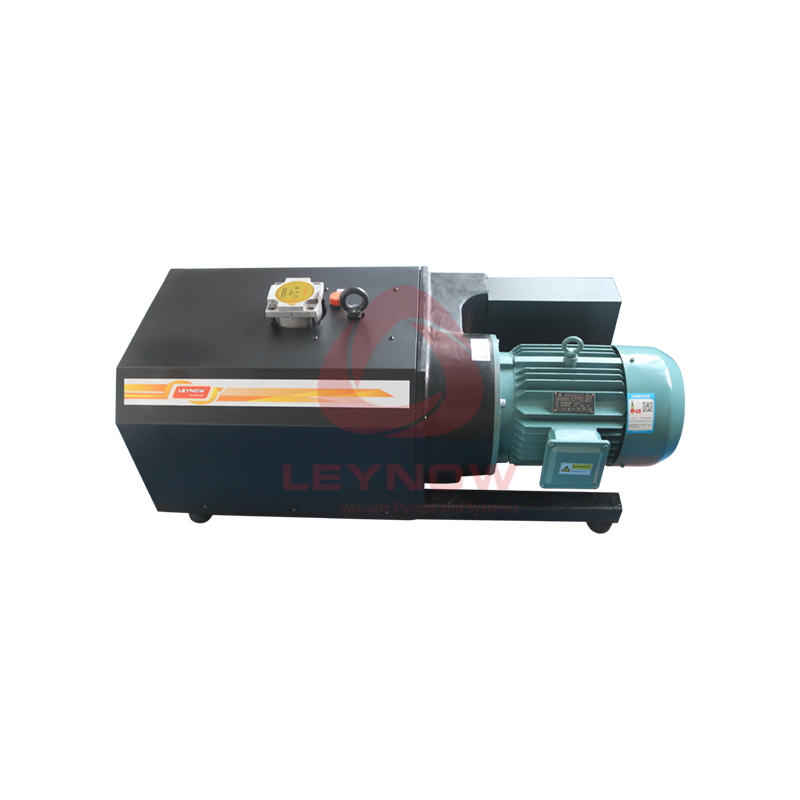

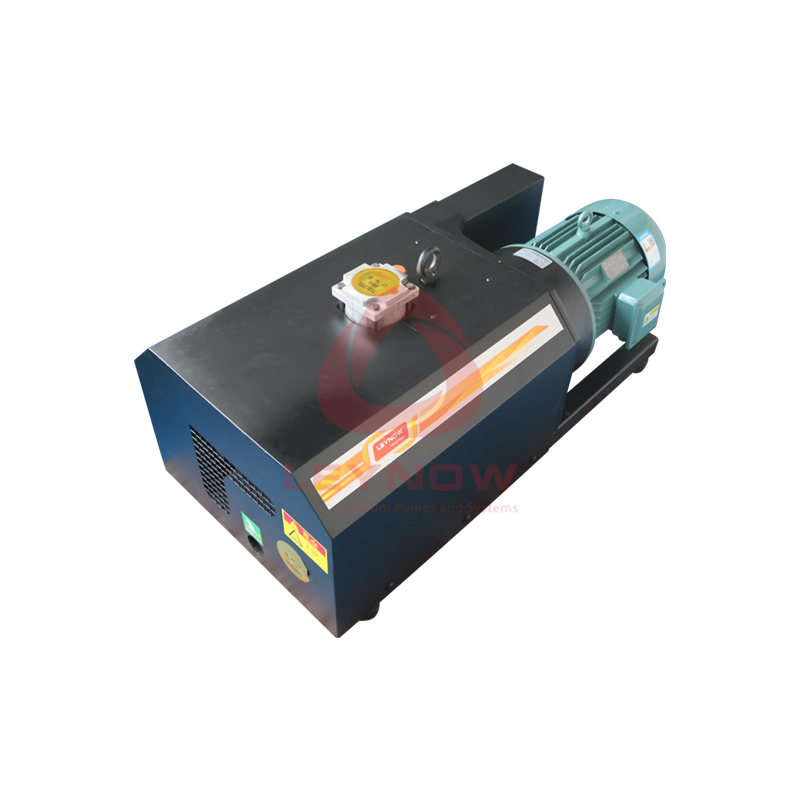

Air compressors are used in a whole variety of transit applications that include main line trains, light rail trains, underground trains, trams, metros, hybrid buses, electric buses, etc. With the focus on reducing energy consumption and the move towards more sustainable energy forms, the use of electrically driven compressors with an on-demand control system is increasing. The vane compressor is ideal for both new build and retrofit transit applications as it is an integrated unit offering 'plug and play' capability.

Compressed air is used for braking systems, suspension systems, door operation, floor leveling systems, pantographs, wipers and claxons. Following the example of transit applications, transport is also moving towards electrically powered vans and trucks which require electric compressors supplying air for the braking and suspension systems.

Blower and vacuum applications

Bulk dry goods

Gardner Denver Transportation Solutions offers a variety of compressors and blowers to discharge materials at optimal speeds and in the safest manner. Unloading dry granular materials from tank trucks by air is the most efficient and economical method of transporting materials. Pellets size and other discharge conditions can vary significantly.

Other factors that influence making the right choice include tank truck layout, fuel costs and discharge location characteristics. A variety of machines are available for processing at optimal rates at low or high pressure from powders (cement, flour and lime), tiny particles (sugar, sand and salt), granules (plastic pellets and grit) and irregularly shaped materials (animal feed and Remove all materials from Mining Materials).

liquid transport

Liquids are shipped around the world, as are fuels, food, waste, chemicals, or used in other processes. We have been working with our customers in this field for many years, so we understand their needs clearly and develop products that can create maximum benefits for our customers. We apply a wide range of technologies to produce fans, compressors, vacuum pumps and cargo ship pumps that can complete their tasks in the shortest possible time while minimizing fuel consumption.

Liquefied gas transportation

For liquefied gas offloading, Gardner Denver developed two systems to drive cryogenic pumps on tank trailers. Hydraulic system: This is a high-pressure, high-flow hydraulic system used to drive the hydraulic motor connected to the cryogenic pump.

Electric drivetrain: This system uses an alternator installed on the tractor. The hydraulic system rotates the alternator via a tightly coupled hydraulic motor. The electricity generated is delivered to the trailer, driving an electric motor that is tightly coupled to a cryogenic pump.

power transmission

From special applications on common vehicles to niche utility, construction and defense vehicles, there is an urgent need for innovative gear transmissions. Webster Drives offers a range of advanced products and collaborates to develop new designs for specific needs.

A range of powertrains, gearboxes, PTOs and gearboxes are used by customers across the globe in a variety of sectors including: automotive, marine, oil and gas, energy, construction, defense and military. The company's design and engineering department has extensive expertise and experience in gear and chain drive development to meet different application needs.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN